Clutching at straws by Frank Massey

13 plate Audi 1s don’t often go wrong, when a dual control driving instructors vehicle time is in short supply. Clutch and brake pedal switches have been around for some time. Their purpose has expanded for several reasons.

With the advantages of short stroke over square engines,especially diesel powered turbo vehicles producing very high lowdown torque outputs. The need to smooth out gear change stress on the transmission is helped with torque reversal strategies. The clutch switch provides an input request, reducing fuelling and re-introducing fuelling by smoothing out fuelling quantity.

This can be achieved in several subtle ways of phasing injector control.

Vehicle starting safety has also introduced the need for clutch pedal operationmonitoring, leading to stop start requirements. Simple stepped voltage change has been replaced with hall sensors.

Our particular problem vehicle was compounded by the need of a block booking. The symptoms were straightforward enough no crank start, correctly attended and predicted to be a clutch pedal sensor by the AA. I say predicted because there was no dtc to suggest any problems!

The patrolman did however apply a common sense opinion based on the fact that a quick push started the vehicle every time. Conducting a global scan withthe autologic platform re confirmed no dtc’s, hoverer the devil is always in the detail. View the response in measuring dynamics this confirmed no binary data response to pedal sensor value when depressing the pedal. The more obvious clue was the dashboard message to depress the clutch pedal whilst engaging the start button.

The pedal sensor is a bidirectional hall device, so let’s list the possibilities,

- a wiring error

- a sensor error

- operational environment error

The next dare I say sensible action would be test its output with our pico, however David decided upon some lateral thinking. Based on the principles of hall sensor operation, a change in the magnetic field across the hall IC leads to a change in the applied voltage. Enquiring as to the contents of my tool box I produced a small rectangular magnet.

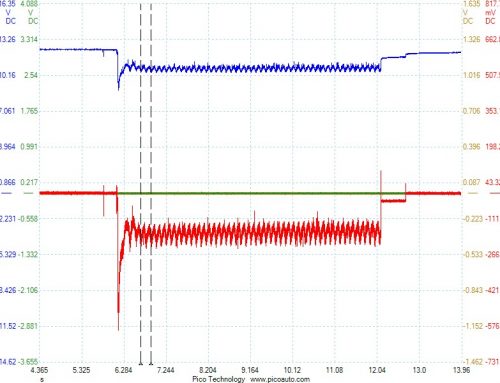

With the sensor removed from the clutch master cylinder it was possible to extend the wiring so that the magnet could be passed across it whilst monitoring live data.The result confirmed a binary change from 0 to1. Conclusion! The sensor was ok the problem was an operational environment issue within the hydraulic cylinder.

In view of the urgency a vor order was placed for a replacement hydraulic cylinder. Unusually for TPS the wrong part arrived so more joint lateral thinking, why not leave the magnet in a binary 1 position allowing the starter to be engaged! And so it was a temporary repair allowing use of the vehicle. The only down side a dtc was now present preventing operation of the stop start function, not a bad swap though. The correct part was in short supply, eventually when fitted all dtc’s cleared and full operation was restored.

Leave A Comment