AUDI TTRS, 8J ENGINE CDLB

Faced with a, Audi TTRS from a well-respected vw specialist we just know it’s not going to be straight forward. Let’s begin with the facts, a new injector had been fitted, not sure why! And the good old chestnut a new intake swirl flap motor. Following which the vehicle ran badly, by badly I mean rough & erratic idle worst when cold.

However open road drivability was not that bad from a casual observation, no dtc present and no obvious deviation or correction factors to guide a potential repair strategy.

We began looking at serial data values for clues especially in the obvious areas of fuelling and ignition misfire count & set back. Let’s focus on a simple process and direction to begin with, I don’t like the expression misfire! It suggests a particular line of enquiry. combustion anomalies is where I’m @ , this leaves 3 possible causes , ignition defects , fuelling errors , and mechanical faults . Yes you can expand in all directions from here but it’s a sound base from which to begin.

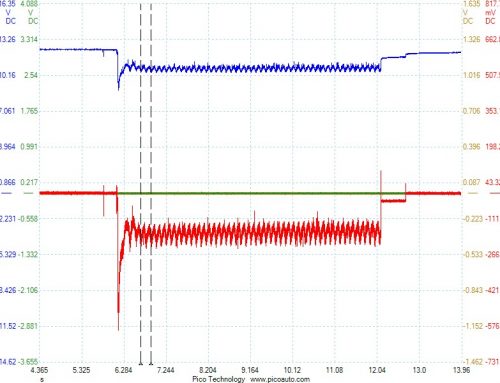

Removing the spark plugs in order to examine colour, condition, & application. The condition did suggest incomplete combustion, standing at the exhaust pipe easily confirmed that so why? We decided to conduct a compression test, a bit obvious but often overlooked. We use the Pico scope and our modified pressure transducer kit for this purpose. Removing the one – way valve so that we can run the engine observing suction and compression in real time with all the environmental influences present. These include, heat, motion, oil pressure, etc.

No obvious problems here pressure peaks looked well and so did the sub atmospheric pressure deviations, I just hate the expression suction or vacuum, its pressure Jim but not as you know it.

Of course this test is conducted on cylinder at a time running in 3 cly mode. Next action focused on re-setting the adaptive values, in tank pump, hp actuator, runner flap position and throttle position. At first we sensed an improvement, it was snowing a week ago and in the morning it still ran rough from cold, the thing I noticed was an obvious improvement as it warmed up!

The next approach was more instinctive than factual, flushing the engine and adding a fuel system cleaner. Once again an improvement was noted but it still was not clean at idle. One thing we all noticed from the outset was a smell of ammonia ( NH3 )! This suggested the process of combustion was not chemically correct, contaminated fuel maybe, this would tie in with the slight plug fouling.

The tank was emptied quickly with actuation via VCDS. Fresh 98 octane fuel added and a thorough road test conducted. Left overnight to go thoroughly cold and he –presto all was good.

I have a theory! And a suspicion that fuel with a high bio-ethanol content was in the tank. Bio fuel when used in concentration over e5 /e10 when run in a non-flexible fuel engine will cause poor combustion especially when cold. Firstly it only evaporates at 78 deg, requires a greater quantity, and timing retard modification before adequate combustion can take place. In fact it also has modified fuel delivery timing, split injection, and a manifold injection as well as direct injection.

Take a look at the schematics of the AUDI 888 engine, two sets of injectors employing both manifold and direct fuel delivery. You may have also noticed stickers inside fuel filler flaps warning against bi-fuel. Whatever it was I am not entirely sure but my money in on the fuel.

Why ammonia NH3 ! incomplete combustion could produce ammonia , nitrogen from the atmospheric intake gasses with fuel residuals HC , the smell could well have been the key to the problem .

Leave A Comment